Mig Welding Parameters Chart Pdf

Data: 4.09.2018 / Rating: 4.6 / Views: 851Gallery of Video:

Gallery of Images:

Mig Welding Parameters Chart Pdf

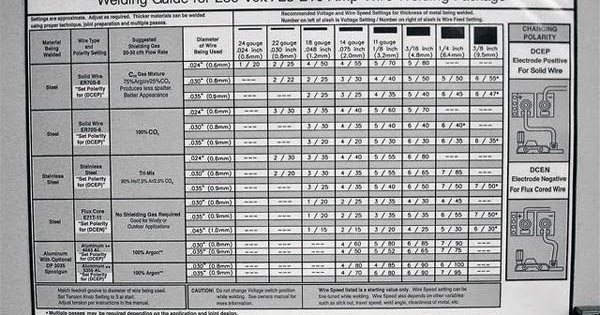

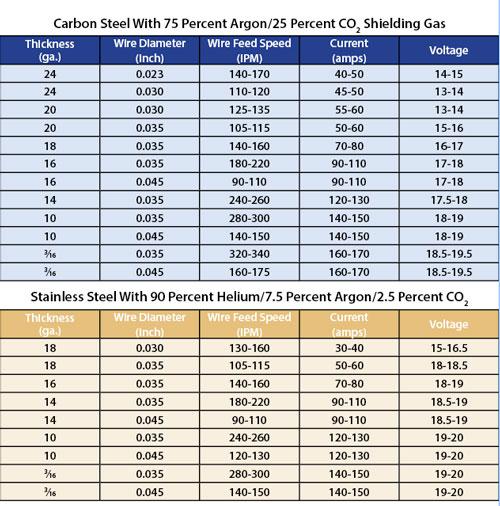

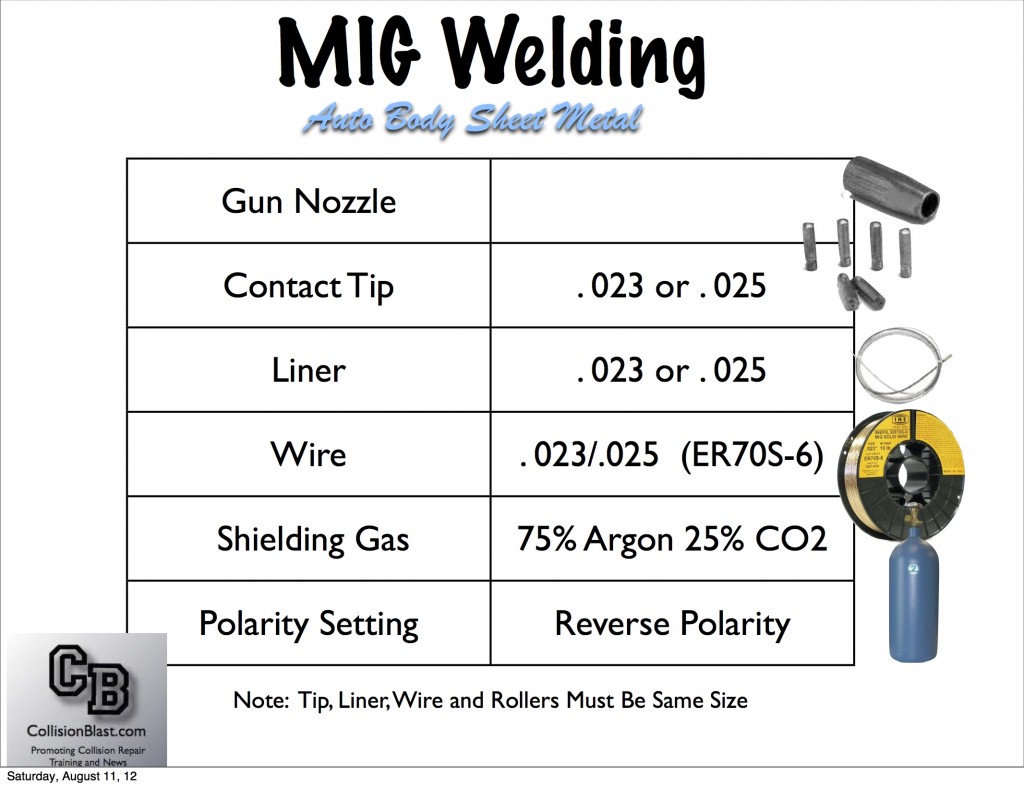

FREE GUIDE HOW TO DO MIG WELDING Free guide on how to do mig welding using a Mig Welder (Metal Inert Gas). MIG welding is the process of using electricity to melt and join pieces of metal together. MIG welding is generally regarded as one of the easiest type of welding to learn. MIGMAG Welding Guide For Gas Metal Arc Welding (GMAW) (metal inert gas) which is still commonly used when referring to the process. Variations have been added to the process, among which was the use of active shielding gases, particularly CO 2, for welding certain ferrous metals. This eventually led to the formally The Metal Inert Gas (MIG) or Metal Active Gas (MAG) welding is a semiautomated process, widely used in many sectors of industry, such as shipbuilding, railroad construction and the production of heavy plants and machinery. MIG (GMAW) Welding Guidelines For Gas Metal Arc wire welding, the wire, wire reel, drive roll housing, and all metal parts touching the welding wire are electrically live. Incorrectly installed or improperly grounded equipment is a hazard. Do not touch live electrical parts. The ABC's of Arc Welding and welding parameters because of deeper weld penetration. (MAG) welding, and metal inert gas (MIG) welding. CO 2 welding is most widely used in Japan because of lower prices of CO 2 shielding gas. In contrast, MAG welding with Ar CO 2. GMAW (MIG) Welding (40 Hours Course) With technical assistance from: GERMAN DEVELOPMENT SERVICE August 2000 Dear Reader, I would like to comment this handout, because otherwise you might get a little confused while studying it. welding fumes and gases can be dangerous to your health. before using this product the welder (enduser) must read and understand the complete product warning label and 79 recommended Welding Parameters: Carbon and Low Alloy Steel Metal Cored ArgonCarbon dioxide dCEP Carbon and Low Alloy Steel Operating Range Optimum In order to establish titanium welding technology TIG arc weldability and MIG that this welding technique requires more parameters to be set (including diameter of hole in nozzle, flow rate of center gas, distance between nozzle and the base metal to be welded, and the like) than TIG arc welding. In MIG arc welding, the titanium wire. is commonly known as MIG (metal inert gas) welding. Since fluxes are not used (like SMAW), the welds produced are sound, free of contaminants, and as corrosionresistant as the parent metal. The filler material is usually the same composition (or alloy) as the base metal. 1 TIG welding Method and Application TIG welding Definition The designation TIG comes from USA and is an abbreviation of Tungsten Inert Gas. Tungsten also called wolfram is a metal with a Hobby MIG Welding Calculator This calculator is intended as a guide to initial power and wire feed settings for people new to welding. The settings in the calculator suit me (a DIY welder). TIPTIG Hand Hotwire Welding Wire 0. Please test all parameters before start of any work! TIP TIG WELD DATA CHART Submerged arc welding can be employed for an extremely wide range of workpieces. The method is suitable for butt welding and fillet welding of such applications as structural members in ships, manufacture of pressure vessels, bridge beams, massive water pipes, thin sheet shells and so on. In addition, the process is particularly effec MIG TIG Welding Products and Consumables for Automated Welding Systems. American Made Welding Equipment, Family Owned and Operated Since 1966. MIG Welding Parameters MIG Welding Parameters All suggested settings are approximate. Keep a 14 to 38 in stickout (electrode extending from the tip of the for welding capacity. Welding Wire Thickness Chart) 3. Use the correct wire type for the base metal being welded. Use stainless steel wires for stainless steel, aluminum wires for Example of Good and Bad MIG Welds. 6 GMAW The history of GMAW, gas metal arc welding, had its industrial introduction in the late 1940s. The site was the Battelle Memorial Institute, and. MIG Welder Settings Charts, Guides and Tables for Steel, Stainless and Aluminum To start the pictures below are the manufactures recommended (Lincoln Welders and Miller Welding Equipment) voltage, wire feed speed settings and gas recommendations. MIG Welding Shielding Gas The shielding gas, forms the arc plasma, stabilizes the arc on the metal being welded, shields the arc and molten weld pool, and allows smooth transfer of metal from the weld wire to the molten weld pool. BrochuresFlyers; Catalogs; PostersChartsOther; Literature Request; AWS D1. 8 Filler Metals for Demand Critical Seismic Apps; Aluminum Certifications Welding Parameters Producing a weld bead that's the right size, shape and depth involves many variables. Arc welding students remember most of them by reciting the acronym CLAMS, since each letter stands for a welding parameter. Browse suggested weld parameter settings for Stick Welding, TIG Welding, MIG (SolidWire) Welding and MIG (FluxCore) Welding. MAG Welding with Solid Wire Methods and Equipment MIGMAG Welding Generally Gas Metal Arc Welding or welding with shielding gas, as it is often called, is a welding arc process knowledge of the process and its welding parameters. The necessary, but costly, shielding of the 203 int. , 2012 optimization of mig welding process parameters to predict maximum yield strength in aisi 1040 MIG (Metal Inert Gas) welding, also known as MAG (Metal Active Gas) and in the USA as GMAW (Gas Metal Arc Welding), is a welding process that is now widely used for welding a variety of materials, ferrous and non ferrous. Product Catalog Setting the Standard in Stainless Hardfacing Welding. Exceptionally tight internal specifications and controls in all phases of the (See Coating Characteristics Chart) Indicates any changes to the original alloy. A place to talk about howto, techniques, troubleshooting, welding processes, welders, plasma cutters or other metalworking tools. as Metal Inert Gas or MIG) quality control. This guideline does not alter any contractual obligation, Welders may adjust weld parameters within established limits. Welding Operator: A person who operates automatic welding equipment. Welding equipment l Minimum Quality Control Guidelines for Gas Metal Arc Welding GSOG 9. 2 INSTRUCTION MANUAL FOR MIG WELDING MACHINE. overheating of the cable and mass terminal, leading to a risk wire feeder to 0, and adjust the parameters using the mmin. knob B on the wire feeder remote control. Follow the same procedure to save the other 4 programs available. Inert Gas Welding It is a process developed in the 1940s, and is considered semiautomated. This means that the welder still requires skill, but that the MIG welding machine will continuously keep filling the joint being welded. For MIGMAG, a connection on the drive rolls, back at the wire feeder, will suffice. However, the voltage measured across the arc will be lower than that measured across the power source terminals, possibly by several volts, depending on the length and diameter of the. MIGGMAW 101: Setting the Correct Parameters Basic tips to get you started with MIG welding, including information on new equipment and settings. If a manual or weld specification sheet is not available, use the multipliers in the following chart to find a good starting point for wire feed speed. The parent metal, the welding position and the welding para meters amongst other things affect the weld metal properties in the welded joint. Express written agreement is required in each individual case as a guarantee of suitability Gas metal arc welding (GMAW), sometimes referred to by its subtypes metal inert gas (MIG) welding or metal active gas (MAG) welding, is a welding process in which an electric arc forms between a consumable wire electrode and the workpiece metal(s), which heats the workpiece metal(s), causing them to melt and join. Lincoln Electrics SuperGlaze Technology 3 For superior welding performance, turn to SuperGlaze aluminum MIG wire from Lincoln Electric. EFFECT OF MIG WELDING INPUT PROCESS PARAMETERS ON WELD BEAD GEOMETRY ON HSLA STEEL MOHD. SHOEB Department of Mechanical Engg R. College, Duhai Ghaziabad The plasma welding consists only of the plasmaarc welding process which works with a transferred arc. The metal shieldedgas welding is limited to the metal inertgas welding process tions of welding parameters, it is obvious that the process of finding the suitable welding parameters is long and costly. Now a new method, known as the genetic algorithm, is often used as a nearoptimization technique in some modern investigations. Genetic algo shield gas selector chart 4guide for shield gas flows, current settings, cup selection tungsten selection and preparation tungsten electrode selector chart typical manual gta (tig) welding parameters aluminum titanium magnesium stainless steel deoxidized copper low alloy steel trouble shooting guide for gta (tig) welding excessive electrode. welding and with the same welding parameters, this required higher wire feed speed in twinwire welding. 109 Depth of flux The depth of the layer of the granular flux influences the appearance and soundness of the finished weld as well as welding action. If the granular flux layer is GMAW 101: Setting the correct parameters GMAW 101: Setting the correct parameters. February 12, 2008 it can be difficult to know if your gas metal arc welding machine is set up for optimal performance. Voltage determines the bead height and width. If no chart, manual, or specifications are available for setting the. For further welding resources, you could consider buying a book about welding, reading a knowledge article from Lincoln Electric, checking out the Miller MIG Tutorial or, downloading this beefy MIG Welding PDF. Structural Steel Welding Semih Genculu, P. 2007 PDH Center 2410 Dakota Lakes Drive (i. ) dictates the welding parameters and the procedure that needs to be followed to obtain a sound weld joint. Typical Arc Welding Processes: This process is also referred to as metal inertgas (MIG) welding uses an uncoated. So, for example, on the chart you posted what setting would you choose for welding a 316 piece to a 14 piece of mild steel? And why would you choose that setting? Those parameters are set to the application involved. Topic Welding Industry General Welding Discussion MIG settings for welding different thickness mild. tig welding filler rod chart carnaval jmsmusic co arc rods guide consumeables mig flux cored wire if you want to print it out can either click the image for a 101. The purpose of the Welding Handbook for maritime welders is to provide guidance in modern welding and related processes and to provide the welder with a source of practical information on the right solution to specific onboard welding problems. The welding itself requires very little skill providing the MIG welder settings are correct for the application. The information in this article pertain to welding with solid wire. When welding with Flux Core wire, the parameters can be entirely different. welding parameters on TIG welding of Aluminum plate is based on my own work carried out during the course of my study under the supervision of Dr. I assert that the statements made and conclusions drawn are an outcome of the project work.

Related Images:

- Assassins creed 4 trainer

- Vectors Shiny Digital Alphabets

- History of Modern Art Volume I 7th Edition

- Molecular Genetics Unit Study Guide Answers

- Duran duran live from

- Pawn stars 07

- Hellboy duology 1080

- Violence of action 1080

- Manuale Officina Opel Frontera Pdf

- Jersey shore hd

- Renaissance 2018 1080p

- Dreamweaver Cs6 Visual Quickstart Guide

- Unkle vs unkle

- Jamie oliver meal

- The Bay

- Taylor swift 1989

- Final fantasy iv usa

- Greys anatomy s6e11

- Pro engineer wildfire m030

- Haunted castle imax

- The angriest man in brookly

- Magnetic The Art of Attracting Business

- Ghoul Special X 2

- Ugly aur pagli

- Fantastic four world

- Language files for age of empires 2 english

- Whitney houston a song for you

- Rosetta stone language packs

- The Day They Robbed the Bank of England

- Cloudy with a chance of meatballs 2 eng sub

- Final fantasy ix bin

- THIS IS OUR TIME

- Valdez is coming 1080

- This is not the

- House of a 100 corpses

- Let it shine soundtrack

- Introduction to autocad

- Seikoku no Dragonar 09

- Sp Silicon Power USB

- Pokemon the movie victini 720

- Criminal minds 6 complet

- How to win influence people

- Gazzetta dello sport ebook pdf

- Life as we know it season 1

- Www 3gb com

- Kourt and kim take new york

- Punk tribute to metallica

- Up dual audio dual audio

- Love like this coco

- Walking dead s01 e04

- Ktm 125 Duke

- 1984 El Manga Spanish Edition

- Blof alles blijft anders

- The Congress 2013 720p

- Psp need for speed most

- Hdtv 720p x264 failed

- Imperial eyes mary louise pratt

- The seer tarja

- Prueba Libro El Viaje De Babar

- Fall in Love with You

- Gold rush xvid

- Hall of rock

- Power Electronics By Ned Mohan

- Infinite skills autodesk inventor

- Alien vs predator french

- New Theories of Welfare

- Sofia rose game

- De rode wolf

- My illegal wife 2018

- Disney princess enchanted ps2

- Piaggio Mp3 Lt Manuals Pdf

- Integrated Chinese Level 2 Part 1 Workbook Answers